barrier film.pptx

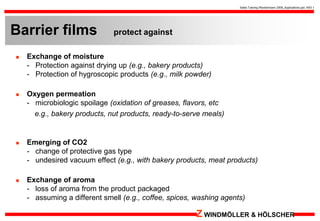

- 1. Barrier films protect against Exchange of moisture- Protection against drying up (e.g., bakery products)- Protection of hygroscopic products (e.g., milk powder) Oxygen permeation- microbiologic spoilage (oxidation of greases, flavors, etc e.g., bakery products, nut products, ready-to-serve meals) Emerging of CO2- change of protective gas type- undesired vacuum effect (e.g., with bakery products, meat products) Exchange of aroma- loss of aroma from the product packaged- assuming a different smell (e.g., coffee, spices, washing agents)

- 2. Oxygen Permeability of different Polymers Standard konditions 23°C, dry

- 3. Oxygen Permeability of EVOH Verbund: PE/ HV/ EVOH/ HV/ PE

- 4. EVOH = Ethylen Vinyl Alkohol Copolymer Handelsname: Soarnol (Nippon Gohsei), EVAL (Kuraray) Gas Barriere Resin ( z.B.: O2, CO2...) High Oil- Resistance High Transparency Charakteristic is the ethylen content of EVOH 104 103 Oxygen Permeability (cm3 20µm/ m2 24 h Pa) 102 101 100 10-1 100 0 Ethylen content [%] Ethylen content [%] Improvement of processability Function of ethylen: Improvement of water resistance

- 5. Structure of Barrier Films

- 6. 5- Layer- Barrier Films

- 8. Deep-drawing film (base film, tray film)

- 11. Heat-Sealing of Deep-Drawing Films Sealing heat is applied from above ! standard: 130 -140 °C ( 1,5 sec) faster: 140 -150 °C (<1,5 sec) PA HV PE Lid film (70-120 µm) A temp. difference at the melt.point isrequired to prevent film sticking tothe sealing jaw ! Barrier layer Sealing layer (LDPE, LLDPE, EVA, mPE, Surlyn) asymmetric ! PE HV PA HV PE Tray film (150-350 µm) Symmetric structure possible, since forming part issilicone coated ! Silicone coated

- 12. Barrier film for foam trays Barrier lid film Seal Legend:A - heat-resistant layerB - tie layerC - gas barrierB - tie layerD - sealing layer Barrier tray

- 13. CONTACT US Express Plaspack (Thailand) Co.,Ltd 1480 Moo 9 Old Train Road, Teparuk, Muang, Samutprakarn, 10270, THAILAND Tel. (66 2) 755-0778, 755-0757, 757-9099 Fax. (66 2) 755-0730 Email : sales@expressplaspack.com