Chemical Client SIPOC

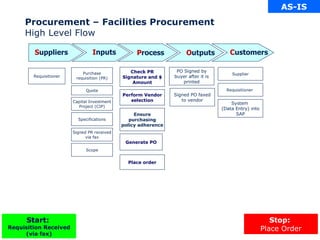

- 1. Procurement – Facilities Procurement High Level Flow Supplier Requisitioner Purchase requisition (PR) PO Signed by buyer after it is printed Perform Vendor selection Check PR Signature and $ Amount Ensure purchasing policy adherence Start: Requisition Received (via fax) Stop: Place Order AS-IS Generate PO Place order Requisitioner Quote Capital Investment Project (CIP) Specifications Signed PR received via fax Scope System (Data Entry) into SAP Signed PO faxed to vendor C ustomers O utputs P rocess I nputs S uppliers

- 2. Procurement – Facilities Procurement High Level Flow - Findings 1 Need to have custom report created to improve facilities purchasing spend management Secondary KPI custom report needed 5 Review current SAP package with team to assess; 1) what is currently available, 2) canned vs custom reports 3) hierarchy (reports / purchasing process) SAP functionality – facilities does not have insight 6 Would like SAP functionality that would convert a PR # into a PO #. This would aid in tracking PR / PO conversion / status No functionality to move a PR# / PO # 7 Route the PO electronically to the controller to tie the purchase to the sales tax code prior to going to the buyer The current PR / PO process has gaps regarding tax code 3 Instead of receiving PR’s via fax receive electronically and have queue by buyer Buyer queue (i.e., waiting PR’s) by buyer # 4 Availability for plants to attached supporting docs to PR. Does SAP have capability to attach documents? Attachments supporting an RFQ are faxed to facilities 2 Electronic signature on PR. Appropriate signature level from operations and plant controller AS-IS process mandates the use of the fax machine to provide signed PR to facilities team Priority Opportunity Finding

- 3. Procurement – Facilities Procurement High-level Flow Findings 2 Since autofax is currently not stable enough for team to have confidence in the buyers can not use. Buyer would like functionality to send the PO and supporting documents to the supplier via EDI, where supply base capabilities exist PO to supplier is a manual process via autofax 1 Would like to use the SAP functionality to assign smart PO #’s A book is kept by each buyer for generating PO #’s. 5 Investigate SAP Functionality No ability to split storeroom PO volume by vendors 4 Instead of continuing this manual process, SAP needs to be used as the repository, not paper. And, SAP functionality needs to meet the desired record keeping the boxes on the stamp provide All PO’s and supporting data (faxed PR, faxed bids, etc) are printed and combined into a packet which is then filed. Before this data is filed the buyer will need to stamp the PO and provide checks alongside the boxes which are applicable to the PO. The available options for the stamp boxes are: requisition, authorization, insurance, job authorization, bids, single source & waiver. 3 This needs to be corrected. AZC may want to look at a global supplier database that is controlled centrally to ensure vendor #’s are controlled. Investigate using a parent child relationship for vendors Some vendors have multiple vendor # s Priority Opportunity Finding

- 4. Procurement – Facilities Procurement High-level Flow Findings High Would like the ability to electronically manage vendor performance Vendor Performance Management is not automated High Once MCG’s are rationalized the MGC would be used to group spend by commodity Material Group Codes (MGC) need to be rationalized to a manageable # High Ability to create ad-hoc vendor reports Reporting Priority Opportunity Finding

- 5. Procurement – Facilities Procurement Order Management Requisitioned Requisitioned System Purchase order Goods or services received check PO status Blanket orders Review PO, update as needed Change order request from vendor or requisitioner Start: Vendor Acknowledgement Stop: Requisitioner Receives Goods AS-IS Vendor Acknowledgement Y/N Order Status PO change order to update blanket Vendor call to / from supplier vendor unable to fulfill order, not ON-time & IN-full (OTIF) Status – to advise requisitioner PO Status block = Phone call/ follow-up request from store rm. Requisitioner Check PO status - process after receive vendor acknowledgement. If a Part Number Change, Pricing Change, Lead time Change , vendor no longer carries or obsolete items this would trigger purchasing contacting plant maintenance, engineer, or safety dept. to determine the correct replacement part Storeroom Make the corrections on the purchase order and fax to vendor C ustomers O utputs P rocess I nputs S uppliers

- 6. Procurement – Facilities Procurement Order Management 2 Would like to be able to have a prompt to change incoterms Freight terms can be unique by supplier or unique by PO 3 For multi-year agreements, would like mechanized process to change prices based upon contract specifics. Need to understand SAP functionality Vendor acknowledgement inconsistent by buyer 1 As we review the MRO items and determine options to manage will want further information regarding options for managing: Non-material master items and their inventory level, ability to order from on-line catalog, electronic PR to PO processing, MRO consumption based upon use, improved links to accounting, maintenance, vendor managed inventory, consignment, etc MRO replenishment / procurement process is inconsistent across plants Priority Opportunity Finding

- 7. Procurement – Facilities Procurement Services Rendered & Payables Support Vendor Accounting Vendor Freight exception report Open PO report (not paid), run QTRly Payment Review invoices and blocked report Review daily auto-pays info Review Open PO report Review vendor calls Start: Review open PO exceptions Stop: Close PO & pay invoice AS-IS Review weekly ERS report Review exception report Requisitioned Invoice Weekly blocked invoice report (purchasing responsibility to print) calls from vendor Daily information on auto-pays ERS report - weekly Alchemy invoice issues - live need to go into system, consignment problems, etc. Emails from accounting Closed PO Review accounting emails Manage Invoice Payment Close PO C ustomers O utputs P rocess I nputs S uppliers

- 8. Procurement – Facilities Procurement Services Rendered & Payables Support Intentionally left blank Priority Opportunity Finding

Notes de l'éditeur

- When thinking about the customers – or who the different stakeholders are.

- When thinking about the customers – or who the different stakeholders are.

- When thinking about the customers – or who the different stakeholders are.