Garments Manufacturing Flow chart

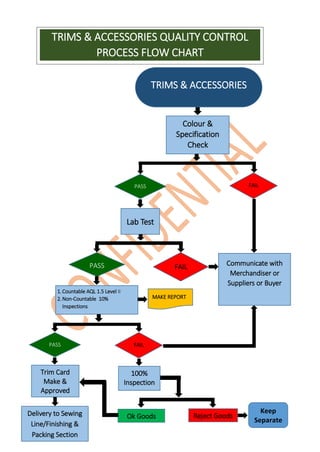

- 1. FAILPASS 1.Countable AQL 1.5 Level II 2.Non-Countable 10% Inspections Trim Card Make & Approved MAKE REPORT 100% Inspection Ke Reject GoodsOk Goods Keep Separate TRIMS & ACCESSORIES QUALITY CONTROL PROCESS FLOW CHART TRIMS & ACCESSORIES Colour & Specification Check FAIL PASS FAIL PASS Lab Test Delivery to Sewing Line/Finishing & Packing Section Communicate with Merchandiser or Suppliers or Buyer

- 2. FABRIC INSPECTION PROCESS FLOW CHART QA COORDINATOR: 1 ROLL FOR EACH BATCH CHECK (1/2 TO 1/2 MITRE FOR COLOR-SHADE, GSM, TORQUE) RANDOMLY INSPECT FABRIC. MAKE REPORT CONSUME 1 DAY INFORM TO PROCURMENT DEPARTMENT CONSUME 2 DAYS FAIL PASS FAIL SUPPLIER CORRECTION 1 ROLL /BATCH RE-CHECKAWH INVENTORY CONSUME 3 DAYS ANOTHER 10% INSPECTION. MAKE REPORT PASS FAIL IMMEDIATE CORRECTIVE ACTION/SORT OUT RE-TEST & RE- INSPECTION.MAKE REPORT PROCUREMNT DEPARTMENT CONFIRM THE CORRECTIVE ACTION INTERNAL LAB TEST & INSPECTION REPORT FOR COMPARISON WITH SUPPLIER & SUBCORDINATOR REPORT. (FABRIC MINIMUM 10% INSPECTION BY 4 POINT SYSTEM IF QTY SMALL LIKE 0-1000 MTR INSP 100%. MAKE REPORT RE-RECEIVE FROM SUPPLIER CONSUME 1 DAY SMALL QTY LARGE QTY PASS FAIL SEND TO WEARHOUSE CONSUME 7 DAYS CONSUME 2 DAYS FOR AWH CONSUME 1 DAY SEND TO WEARHOUSE Consume 1 day CONSUME 1 DAYS FAIL

- 3. LIZ PRINTING SECTION QUALITY CONTROL PROCESS FLOW CHART Warehouse Fabric/Cut Piece Received Sample FAIL PASS Re-work Inspection Color/Design & Wash Test Results Reports Reports Bulk Production In-line Inspection Color/Design FAIL PASS Results Re-work Reports Running End-line Inspection Workmanship FAIL PassResults Delivery to cutting ReportsRejection/Alteration

- 4. + KEEP RECORD Immediate corrective action/ sorting ROLL TO ROLL SHADE, GSM & ALL LAB TEST REPORT CHECK CUTTING SECTION FLOW CHART FABRIC RECEIVE FROM WEARHOUSE PATTERN TEST (GMTS MAKE) PASS FAIL RETURN TO SUP DELIVERY TO CUTTING SPREADING & LAY HEIGHT MARKER CHECK WITH RATIO PASS FAIL SENT RELAX ZONE DO PLAN COUNTRY & GROUP CUT PANEL CHECK 100% PASS REVIEW FABRIC INSPECTION (4 POINT SYSTEM MINIMUM 10 %) IF FAIL 20% IF FAIL 100% INSPECTION SEND TO SEWING SENT TO PRINT / EMBO 100% CHECK PRINT / EMBO FAIL IF PRINT / EMBO PASS RANDOM M-MENT CHECK MAKE REPORT RE-INSPECTION RE-PROCESS

- 5. MAKE TRIM CARDKEEP RECORD DUPLICATE COUNTER SAMPLE BACK FRONT MATCHING IF RQRD SPI MONITORING CCUSTOMER) SEND TO SEWING SEWING SECTION FLOW CHART PRE PRODUCTION MEETING RETURN TO SEWING FOR RECTIFY CRITICAL PROCESS 100 % CHECK TRAFFIC LIGHT SYSTEM MAKE REPORT KEY MEASUREMENT AREA CHECK MAKE REPORT PASS FAIL MAKE RECORD FIRST OUTPUT CHECK WITH C/S LABEL CHECK PASS INITIAL CHECK MAKE REPORT FAIL SEND TO FINISHING STOP PRODUCTION & ADJUST MACHINE MAKE REPORT KEY MEASUREMTN CHECK AGAINEST FINISHED PATTERN PASS KEEP RECORD PRODUCTION AND QUALITY MEETING TO REVIEW THE ROOT CAUSE OF REJECTION PASS RE- INSPECTION

- 6. FINISHING SECTION FLOW CHART 100% LABEL & KEY POINT MEASUREMENT CHECK PRE FINAL INSPECTION PACKING AUDIT FAIL L MAKE REPORT MAKE REPORT FAIL RE-CHECK MAKE REPORT PASS RECEIVE GARMENTS 100% Garments Trimmings, Thread Sucking & Ironing AFTER PRSSING 100% GARMENTS FINAL QC CHECK METAL DETECTOR CHECK 100% GARMENTS GET UP CHECK SHADE CHECK REPAIR FAIL FAIL MAKE REPORT FAILPASS FINAL QC CHECK READY FOR FINAL INSPECTION FAILPASS RE-CHECK PASS SHORT OUT

- 7. Calibrating (Every 02 Hours on 1.2mm Ferrous Card by following 09 Point System) MAKE REPORT Stop The Machine & Machine Repair. Last 02 hour passing garment recheck. Pass All Goods in Metal Free Zone Mark With Date, Time, Order No, Needle, Action Taken, Signature & Storage It 100% Garments are checked by needle detector (2 Way For all country. MAKE REPORT PASS FAIL FAIL PASS Machine Calibration MAKE REPORT METAL DETECTOR FLOW CHART Metal Detector Machine

- 8. Keep Record with Mark-Date, Time, M/No, Order, Colour, Result & Sign Keep Record with Mark-Date, Time, M/No, Order, Colour, Resul PULL TEST MACHINE FLOW CHART Pull Test Machine Calibration (Daily -6.8kg Weight & Acceptance Tolerance ±5%) MAKE REPORT FAIL PASS MAKE REPORT Collect Garments Every 04 Hours & Test It 90N Minimum 10 second Stand PASS Machine Supplier M/BE Replace or Repair Keep Record with Mark-Date, Time, M/No, Order, Colour, Result & Sign FAIL Last 04 Hour Garments separate & Machine Repair Keep Record with Mark-Date, Time, M/No, Order, Colour, Result & Sign Storage It in Lock Box Minimum 6 Months

- 9. Sample Request Ready For Submission SAMPLE SECTION FLOW CHART Pattern Development Fabric Development Check PASSFAIL Lab Test Cutting Sewing Workmanship & Measurement Check, Pull & Nickel test (if necessary) MAKE REPORT PASS PASS FAIL FAIL Early Risk Assessment & Check Bulk Table QC Check & Wash Test (If Required) MAKE REPORT PASSFAIL